An Update for Employees, Customers, and Suppliers

Case Study: How to Successfully Transfer existing product to new CM

A little over a year ago, a consumer customer approached SAI with a need to transfer their products from their current contract manufacturer to another CM. The customer provides athletic training devices in a very competitive market where quality and delivery are imperative to their paying athletes; after two years of working with the current CM, neither of these virtues have been provided.

The athletic training product company spent a full day at Spectrum Assembly’s manufacturing facility, expressing their needs and goals, including robust supply-chain management, a repeatable assembly process, palletized packaging, and national direct shipping logistics.

For a seamless transfer from one contract manufacturer to another, it is critical Spectrum Assembly understands the product, assembly, and test requirements, as well as material and supply-chain needs.

Spectrum Assembly recommended its Transfer Assist and Turnkey solutions. The customer was eager to execute these programs. SAI formulated a game-plan specific to this customer’s situation. They had materials on order. They had customer-furnished materials at the current CM, and the CM had materials it had purchased on behalf of the customer—as well as subassemblies that would require 100% inspection to the customer’s drawings and specifications.

The transfer protocol included SAI taking receipt of all the available material from both the customer and the current contract manufacturer. Spectrum Assembly began auditing, inspecting, and inventorying the existing materials to provide a seamless transfer. Based on MRP requirements, SAI will maintain the appropriate levels of inventory and source material from approved, authorized distributors.

“We are performing red lines with their engineering teams and ours,” said Topp, “and we are mixing their suppliers and new suppliers for the project. We will buy customer-furnished materials. Then, once the consigned material runs out, we will go turnkey.”

Spectrum Assembly is committed to high-quality standards, using the latest technology; transparent supply-chain management with full traceability of the product assembly process; comprehensive testing capability; the capacity to rework down revision products; and open customer communications that foster an ongoing relationship built on trust.

Spectrum Assembly is working hand in hand with the consumer athletic device customer to make the transfer process as harmonious as possible. Careful planning has been the key to executing an in-depth transfer from one contract manufacturer to another.

In a year’s worth of project planning, Spectrum Assembly is more than optimistic the transfer will be a great success for all parties involved, with clear roles established, all materials tracked, communication channels open, and testing processes and procedures meeting compliance standards.

SAI Brings Conformal Coating In-House with PVA Delta 6

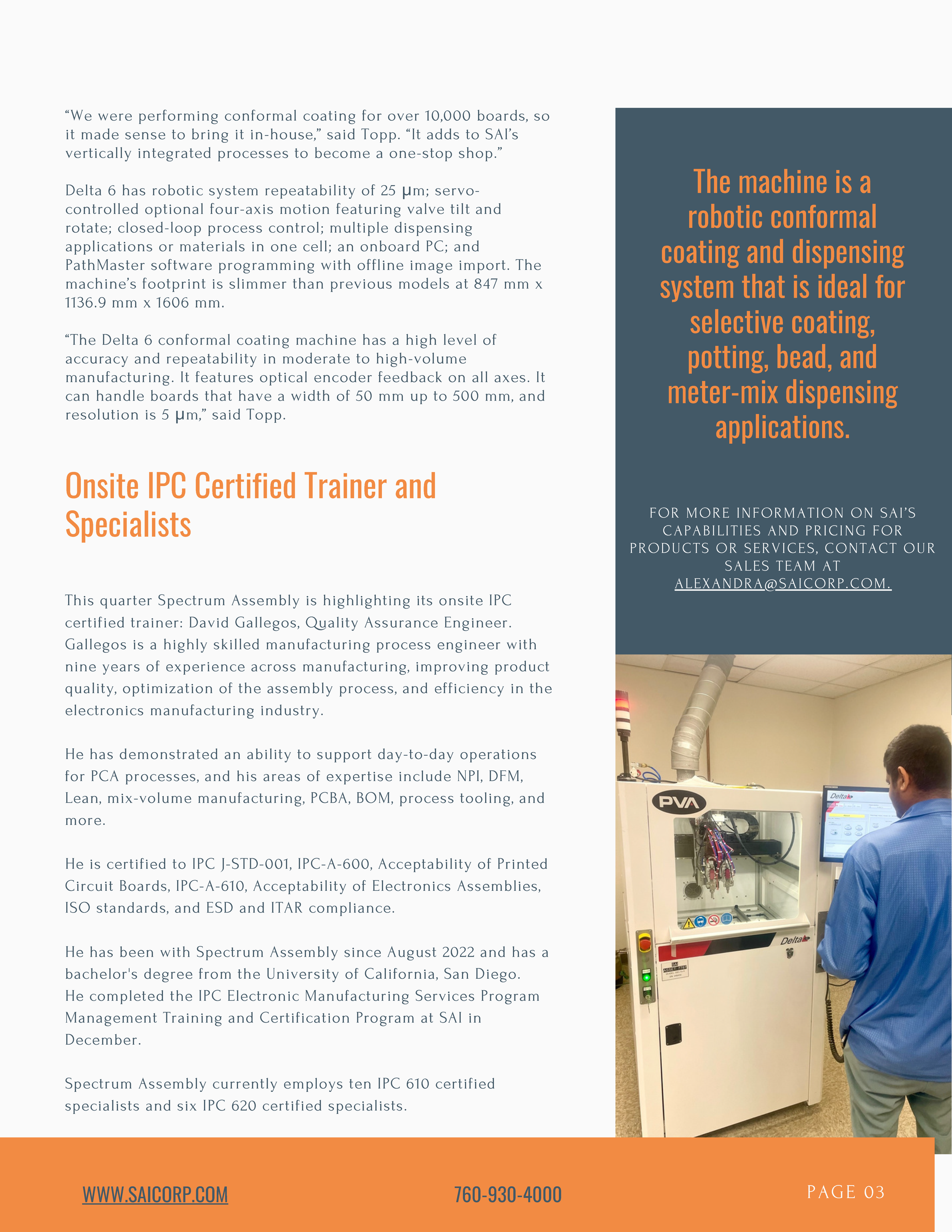

Spectrum Assembly is now the proud owner of a PVA Delta 6 selective coating/dispensing system. The machine is a robotic conformal coating and dispensing system that is ideal for selective coating, potting, bead, and meter-mix dispensing applications. It features an overhead three-axis motion platform for inline and batch operations.

“We were performing conformal coating for over 10,000 boards, so it made sense to bring it in-house,” said Topp. “It adds to SAI’s vertically integrated processes to become a one-stop shop.”

Delta 6 has robotic system repeatability of 25 µm; servo-controlled optional four-axis motion featuring valve tilt and rotate; closed-loop process control; multiple dispensing applications or materials in one cell; an onboard PC; and PathMaster software programming with offline image import. The machine’s footprint is slimmer than previous models at 847 mm x 1136.9 mm x 1606 mm.

“The Delta 6 conformal coating machine has a high level of accuracy and repeatability in moderate to high-volume manufacturing. It features optical encoder feedback on all axes. It can handle boards that have a width of 50 mm up to 500 mm, and resolution is 5 µm,” said Topp.

Onsite IPC Certified Trainer and Specialists

This quarter Spectrum Assembly is highlighting its onsite IPC certified trainer: David Gallegos, Quality Assurance Engineer. Gallegos is a highly skilled manufacturing process engineer with nine years of experience across manufacturing, improving product quality, optimization of the assembly process, and efficiency in the electronics manufacturing industry.

He has demonstrated an ability to support day-to-day operations for PCA processes, and his areas of expertise include NPI, DFM, Lean, mix-volume manufacturing, PCBA, BOM, process tooling, and more.

He is certified to IPC J-STD-001, IPC-A-600, Acceptability of Printed Circuit Boards, IPC-A-610, Acceptability of Electronics Assemblies, ISO standards, and ESD and ITAR compliance.

He has been with Spectrum Assembly since August 2022 and has a bachelor's degree from the University of California, San Diego. He completed the IPC Electronic Manufacturing Services Program Management Training and Certification Program at SAI in December.

Spectrum Assembly currently employs ten IPC 610 certified specialists and six IPC 620 certified specialists.

So. Cal. Trade Shows Return to Pre-Pandemic Levels

Spectrum Assembly exhibited on the main floor at the annual MD&M West medical device show at the Anaheim Convention Center in Anaheim, California, in early February. MD&M West brings the medical device design-to-market community together to promote collaboration and inspiration for lifesaving technology. The event was a well-attended, local opportunity for Spectrum Assembly to meet with existing customers and suppliers, as well as engage with new customers on full medical device box-build, cable and wire harness assemblies, and PCBA.

“We are actively working on quotes for new customers,” said Alex Topp, Sales and Marketing Manager, Spectrum Assembly. “It felt like we were back in 2019, returning to pre-pandemic levels of attendance and engagement. It has been a long time coming.”

MD&M West hosts over 1,400 exhibitors and boasts some 13,000 attendees.

With in-person trade shows on the upswing, Spectrum Assembly looks forward to participating in the Del Mar Electronics & Manufacturing Show at the Del Mar Fairgrounds in San Diego, California. The exhibition will take place from 10:00 a.m. to 5:00 p.m. on April 26 and 10:00 a.m. to 3:00 p.m. on April 27. Customers and colleagues can find Spectrum Assembly in booths 302 and 304 in the Bing Crosby Hall at DMEMS, a design and manufacturing show for the electronics, medical, and biotech industries with 500 booths and more than 4,500 industry professionals.

“We are excited to return to the Del Mar show, which provides a casual atmosphere to connect with existing and potential customers,” said Topp. “The laidback vibe lends itself to plenty of time for in-depth conversations with attendees. We will see you there!”